Material Requirement Planning – Synchronized MRP Software

Synchronized Requirements Planner

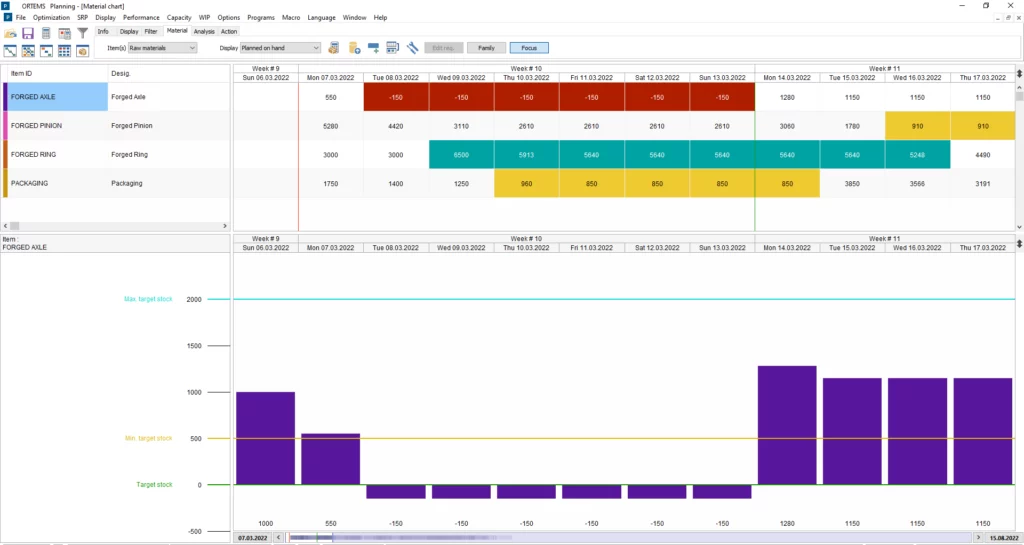

The Synchronized Requirements Planner (SRP) is an indispensable module for Material Requirements Planning (MRP Software) systems, designed to support multi-level Bill of Materials (BOM) structures. As a vital part of the DELMIA Ortems Advanced Planning and Scheduling Software, this module works alongside Manufacturing Production Scheduling Software and Manufacturing Production Planning Software.

Material Requirements Planning Software (Synchronized Requirements Planner) allows users to automate order generation for semi-finished products and establish dynamic connections between them. The system consistently tracks individual production tasks (semi-finished products), adjusting production plans automatically in the event of delays.

Utilizing a synchronized MRP system, SRP can generate orders for all BOM levels while considering machine availability, operations, and material requirements. This module plays a significant role in both production scheduling and manufacturing planning, making it an invaluable tool for creating detailed production schedules within a single APS system.

Benefits of Synchronized MRP Software include streamlined inventory management, enhanced production lead times, and improved accuracy in production planning. The module provides a comprehensive solution for managing complex production processes and optimizing resource utilization. Furthermore, SRP helps in efficiently handling customer demand, capacity planning, and inventory control.

By incorporating SRP into your MRP system, you can ensure optimal material planning, reducing production costs and increasing flexibility in your manufacturing operations. This integration leads to more accurate forecasting of demand, improved capacity requirement planning, and better synchronization of production plans based on available resources, ultimately leading to a more efficient and profitable production process.

Optimize Your Inventory and Material Flow with the Synchronized MRP System - the Synchronized Requirements Planner (SRP) Module

Synchronized MRP Software (Synchronized Requirements Planner) module is a powerful tool for managing multi-level Bill of Materials (BOM) structures in Material Requirements Planning (MRP) systems. With SRP, you can optimize inventory control, efficiently manage raw materials, and implement the Just in Time (JiT) management strategy. This enhances production efficiency and reduces costs, ensuring smooth and efficient production processes, and enabling you to deliver high-quality products on time and within budget.

Automate your Semi-Finished Product Orders

Synchronized MRP Software (Synchronized Requirements Planner) streamlines your manufacturing operations by automatically generating semi-finished product orders and establishing dynamic relationships between them. In case of any delays in one order, the system adjusts all related operations and production plans, helping you maintain optimal production schedules, reduce lead time, and meet customer demand.

The user-friendly graphical interface of SRP makes it easy for planners and authorized personnel to monitor the status of orders, production plans, and inventory levels in real-time, ensuring efficient inventory management and accurate production forecasting.

Enhance Planning and Scheduling with Synchronized Requirements Planner (SRP)

Material Requirements Planning (MRP Software) – Synchronized Requirements Planner (SRP) module creates links between semi-finished and finished products, taking into account the availability of machines, operations, and materials under limited capacity conditions. This results in improved resource allocation and advanced planning capabilities.

SRP is a valuable addition to Manufacturing Production Scheduling Software and Manufacturing Production Planning Software, complementing both order scheduling and long-term production planning for increased efficiency and flexibility in your manufacturing process.

Ready to get started?

Contact us and we’ll get in touch.

With Delmia Ortems Synchronized Requirements Planner (SRP)

- Optimize inventory and stock levels for semi-finished goods to reduce carrying costs and improve inventory control

- Synchronize production orders with current and predictable inventory levels for better resource planning and capacity requirement planning

- Improve customer service and order fulfillment times by anticipating material requirements and efficiently managing production lead times

- Easily configure notifications for overproduction to minimize waste and maximize efficiency

- Simultaneously supply semi-finished products for multiple finished products with Material Overlap Links for a more streamlined and flexible manufacturing process

- Generate a comprehensive Material Requirements Plan (MRP) to enhance production planning, scheduling, and forecasting accuracy, ultimately improving your manufacturing operations

Q&A

Material requirements planning (MRP) comprises all organization’s processes and systems for calculating the materials and components needed to manufacture a product. The MRP system involves cataloging materials and components in the factory, identifying needs of additional materials and components, and scheduling their production or purchasing products and semi-finished products.

The MRP system’s objective is to increase the efficiency and flexibility of production processes. Material requirements planning is executed via dedicated production resource management software, such as the DELMIA Ortems APS system, which considers additional production limitations together with the synchronized MRP.

Bill of materials (BOM) is the list of raw materials, components, parts and their quantities required to manufacture the end product.

Safety stock is an additional quantity of goods stored in the warehouse to reduce the risk of the goods running out of stock. Safety stock serves as a buffer stock when sales are greater than planned and/or the supplier cannot deliver additional units within the required time.

Sales and operations planning (S&OP)? is the process of defining the strategy for achieving the organization’s goals that allows for finding a middle-ground solution satisfying the demands of teams across sales, marketing, finances, operations, and logistics. The use of S&OP helps reduce excess inventory and improve the company’s operations, ultimately resulting in cost decrease.

Supply planning comprises the entire planning process including distribution, production, and supply chain based on demand forecasting, all while factoring in capacity limitations and material availability. The objective of this process is to plan the supply that best meets the demand for the product/service offered.

DELMIA Ortems Synchronized Requirements Planner (SRP) is a solution that allows for creating multilevel bills of materials (BOMs) and joint production orders for semi-finished products used in many end products. SRP facilitates production planning and extensive production scheduling within the single planning system (APS). The solution creates orders for all BOM levels while factoring in the availability of machinery, equipment, operations, and materials under limited performance conditions.

Maintenance management services is a department in a manufacturing company created to ensure that the plant’s technical infrastructure, i.e., machinery, equipment, and installation, are always available and enable the right use of the infrastructure. The department is also often responsible for machinery maintenance, inspections and repairs, the equipment register, and occupational safety and health management.

Traceability is the ability and process of monitoring and tracking the product and its origin of goods across all stages of the supply chain.

Working stock is the amount of materials and number of components that make up inventory required to be available at specific time to ensure effective production optimization.

Manufacturing Planner

Evaluates medium- and long-term production capabilities by identifying production capacity and bottleneck areas.

Production Scheduler

Factors in constraints related to machines, operators, and tools to optimize the production plan, sequence of operations, and raw material inventory. Increases productivity and reduces setup times.

Thousands of companies from various manufacturing industries are already using the APS Production Scheduler. Reach out if you’re interested in learning more about this tool and the benefits it can bring to your company.

Ewa Prokulewicz

Business Development Manager

- eprokulewicz@andea.com

- +48 536 590 357