Manufacturing Production Planning Software

Manufacturing Planner

Manufacturing Scheduling Software – Manufacturing Planner (MP) is a powerful manufacturing production planning module of the APS DELMIA Ortems system that helps organizations improve and expand their production capabilities. This software simplifies the manufacturing process by enabling you to streamline manufacturing planning, gather and manage information on order loads, process efficiency, and delivery times, while considering various variables and their relationships.

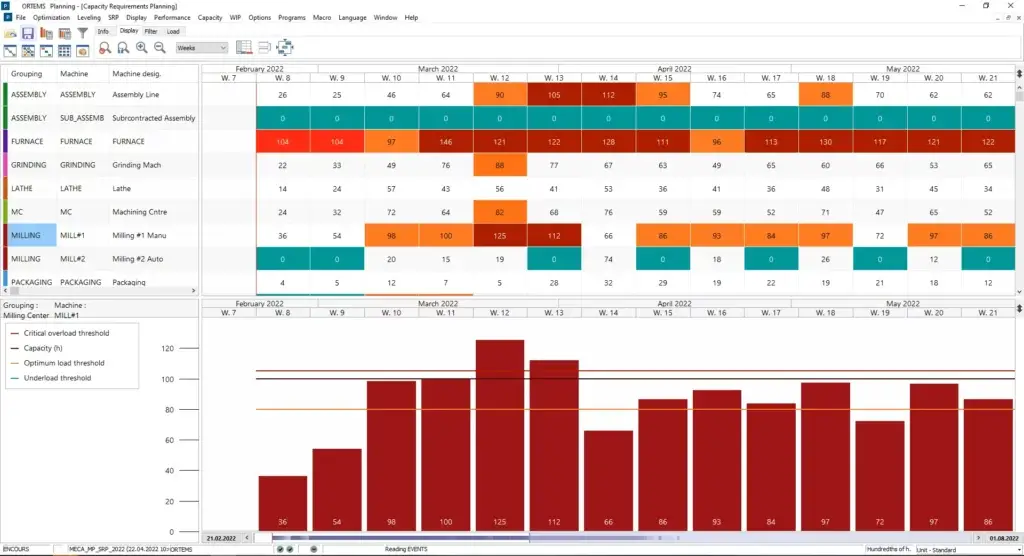

One of the key benefits of Manufacturing Planning System (Manufacturing Planner) is its ability to quickly identify production planning bottlenecks. By providing real time data on production capacity and resource utilization, this software helps organizations improve their factory planning accuracy and respond more flexibly to changes in demand for both internal and subcontracting resources.

Moreover, Manufacturing Planning Software (Manufacturing Planner) enables you to easily modify production plans to respond to performance issues and changes in demand. The real time load leveling mechanism detects instances of overcapacity and recommends actions to balance the load, ensuring optimal performance

With Manufacturing Scheduling Software Manufacturing Planner’s visual planning , you can also map out production operations on workstations using graphical methods. The clear visualization of tasks on a timeline, broken down by specific machines and processes, improves decision-making accuracy and production management quality, ultimately optimizing manufacturing production.

Overall, Manufacturing Planning Software (Manufacturing Planner) is an essential tool for any manufacturing organization looking to improve and expand its production capabilities. By streamlining production planning, identifying bottlenecks, and providing real time data on inventory levels, this manufacturing planning software helps organizations optimize production processes, reduce production time, and achieve their production goals with greater accuracy and efficiency.

Take your Production Planning to the Next Level

Manufacturing Planner (MP) is an advanced manufacturing production planning software that streamlines, accelerates, and automates the development of medium- and long-term plans for your manufacturing operations. This powerful tool enables you to swiftly generate a comprehensive master production schedule, encompassing capacity planning and material requirements planning, to efficiently accommodate new orders and manage production timelines.

Match Plans with Production Capabilities - In just a Few Clicks!

Manufacturing Planning System has never been more efficient! The Manufacturing Planner boasts an intuitive visual planning approach with an easy-to-use graphical interface that simplifies load balancing and plan creation, making complex tasks more manageable.

The powerful visual planning feature allows you to move tasks to different days by simply dragging the colored tiles to new locations on the timeline. The system will automatically update the plan and notify you of any potential issues that arise, such as overloads or conflicts, ensuring you can address problems promptly and maintain a smooth workflow.

This interactive and user-friendly visual planning tool not only streamlines the factory planning process but also fosters better communication and collaboration among your team. Gain valuable insights, spot trends, and make informed decisions to optimize your production process and drive your business forward.

Automate your Manufacturing Planning Process

Experience effortless planning with Manufacturing Production Planner (MP)! Our automated load balancing feature intelligently crafts the most optimized production plan by considering all variables through comprehensive resource planning, including machine availability and secondary resource accessibility. The cutting-edge optimization engine is a time-saving powerhouse that liberates planners from tedious manual work, enabling them to dedicate their efforts to higher-level tasks and strategic decision-making.

Allow Manufacturing Planner’s advanced capabilities to streamline your production process, boost efficiency, and propel your business towards sustained growth and success.

Make your Planner a Superhero

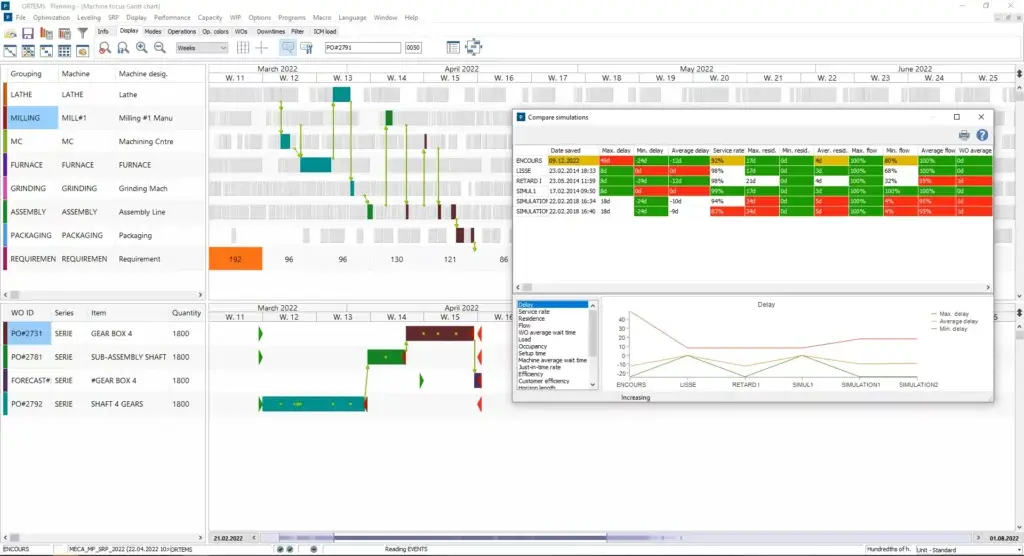

Imagine the edge you’d gain if your employees could glimpse the future! With Manufacturing Planner, that’s within reach. Our planning software module empowers you to explore “what-if” scenarios, enabling you to evaluate diverse production strategies and pinpoint the optimal approach for your business.

Leverage our Manufacturing Scheduling Software module to make informed strategic decisions, like expanding your workforce or investing in cutting-edge equipment, backed by trustworthy data. Swiftly establish feasible deadlines for new production orders and confidently confirm sales orders with your customers, knowing you’ve made the best choice for your operations.

The End the Spreadsheet Era!

As your business expands, managing an increasing number of products, orders, and customers with Excel spreadsheets for production planning becomes progressively challenging. Continuously updating static sheets to accommodate dynamic changes can result in errors that impact your operations.

Transition to Delmia Ortems’ interactive, contemporary interface, and revolutionize your production planning process. With Delmia Ortems, you gain access to real-time production planning, maximizing your factory’s processing capacity and optimizing resource allocation. Embrace the future of production planning with Delmia Ortems and elevate your business to new heights of efficiency and success.

Ready to get started?

Contact us and we’ll get in touch.

With Delmia Ortems Manufacturing Planner…

- Integrate with Delmia Ortems Production Scheduler

- Develop a comprehensive master production schedule

- Optimize your long- and medium-term production plans (in weeks and months)

- Plan production for each individual product

- Analyze your company's production capacity

- Adjust your plan to match production capabilities

- Forecast resource demand

- Balance workloads across your factory to maximize efficiency

- Run "what-if" scenarios for improved decision-making

- Streamline your planning process and reduce inventory levels

Q&A

DELMIA Ortems uses the production model that accurately reflects all production constraints, such as the availability of assembly lines and operators or delivery times. A large number of the plan optimization criteria can be configured in the system—there are more than 80 in DELMIA Ortems.

Based on the entered production model and optimization criteria, the system automatically distributes operations so that the production cycle is optimal, which means as short as possible.

Yes, you can make changes to production orders directly in the production plan. The system will automatically rebuild the plan using new data.

Yes, if we create a plan that considers the availability of raw materials, the system automatically optimizes the plan for this specific criterion. Further, the system provides various material analysis options; for example, the system highlights operations with raw material coverage in green, while operations without coverage and at risk are highlighted in red.

In the DELMIA Ortems system, production planning can be performed on any number of operations—and while there are no technical limitations, there are best practices. We estimate that efficient production scheduling (the Production Scheduler module) best happens on several to dozens of thousands of operations.

For rough-cut capacity mid-to-long-term planning (the Manufacturing Planner module), the number of operations gets bigger and reaches even hundreds of thousands of operations that can be analyzed and optimized in the system.

Depending on the number of operations, the conversion and optimization efficiency is very high. The conversion time takes from microseconds to several minutes (for very complex, long-term production models).

Assemble to Order (ATO) also called custom assembly, is a business production strategy build around keeping the stock level of parts, components, and entire segments high enough, allowing for faster assembly of the end products ordered by the customer. Computer manufacturers are good examples of ATO due to their business model that involves first receiving the order and then using available components, such as a keyboard, monitor, and motherboard, to assemble a computer configured to the requirements.

Batch Production is a production method where the products are made as specified groups or numbers, within a set time frame. The method allows for making temporary changes and modifications throughout the entire production process. Batch production is used in the chemical, petrochemical, food, and pharmaceutical industries.

Continuous manufacturing is a production organizing method where the technological process is continuously executed (24 hours a day and seven days a week) and supplying raw materials and picking up products happens simultaneously and continuously.

Discrete manufacturing is production of finished products that are distinct and countable items, for example, the production of engines or aircrafts. Generally, discrete production is unit-based and involves delivering individual units of the end product.

Digital manufacturing involves the use of computer systems in production, supply chains, and processes. Digital technologies connect systems and processes in all production areas and create an integrated approach to production operations, from design through manufacturing to maintenance and service of end products.

Load leveling is a method for reducing large load fluctuations and adapting production demands to efficiency of resources. The method allows for optimal use of the plant’s production capacity.

DELMIA Ortems Manufacturing Planner (MP) is a module leveraged for planning production capacity for mid-to-long-term time frames. The module’s objective is to ensure production capacity for the implemented production plan.

Production plan is a detailed plan for the kind and quantity of end products to be manufactured and anticipated for manufacturing and includes scheduling the production over the time to allow for executing the sales plan and achieving the anticipated profit. The production plan considers all intertwined technical, organizational, economic, and management factors.

Production Scheduler

Synchronized Requirements Planner

Thousands of companies from various manufacturing industries are already using the APS Production Scheduler. Reach out if you’re interested in learning more about this tool and the benefits it can bring to your company.

Ewa Prokulewicz

Business Development Manager

- eprokulewicz@andea.com

- +48 536 590 357

Make to order (MTO) is a custom production model based on direct request, without long-term plans, with the product fully customized to the customer’s individual specifications, needs, or preferences. This model is used for craft production, building IT systems, the automotive industry, hand-made interior design items, or personalized luxury products.